Extend Life of Assets

Using Rotolining

Saudi Polycon, one of the best companies specializes in Rotolining for corrosion protection.

ROTOLINING | INTERNAL POLYMER LINING

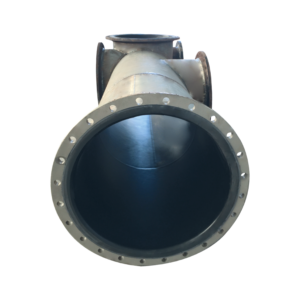

A seamless Polymer Lining technique for carbon steel pipes, fittings, and vessels. Rotolining is a unique process that has recently seen significant advantages in part complexity and material performance. This technique allows for a seamless polymer lining to be applied to the interior surface of metal structures. The use of high performance thermoplastics in Rotolining (internal coating) assures that this process will continue to grow and be accepted as an industry standard.

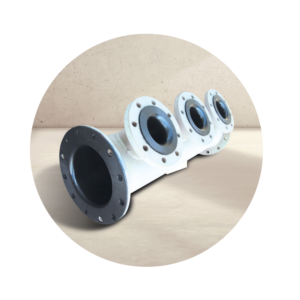

Rotolining applies a uniform, smooth, joint-free and adhesive-free coating/Lining of Polyethylene/ PP / ETFE/ PTFE/ PVDF/ Polyamide etc. on the internal surface of the Carbon Steel Pipe Spools , Fittings , vessels , complex shape etc. with controlled heating process.

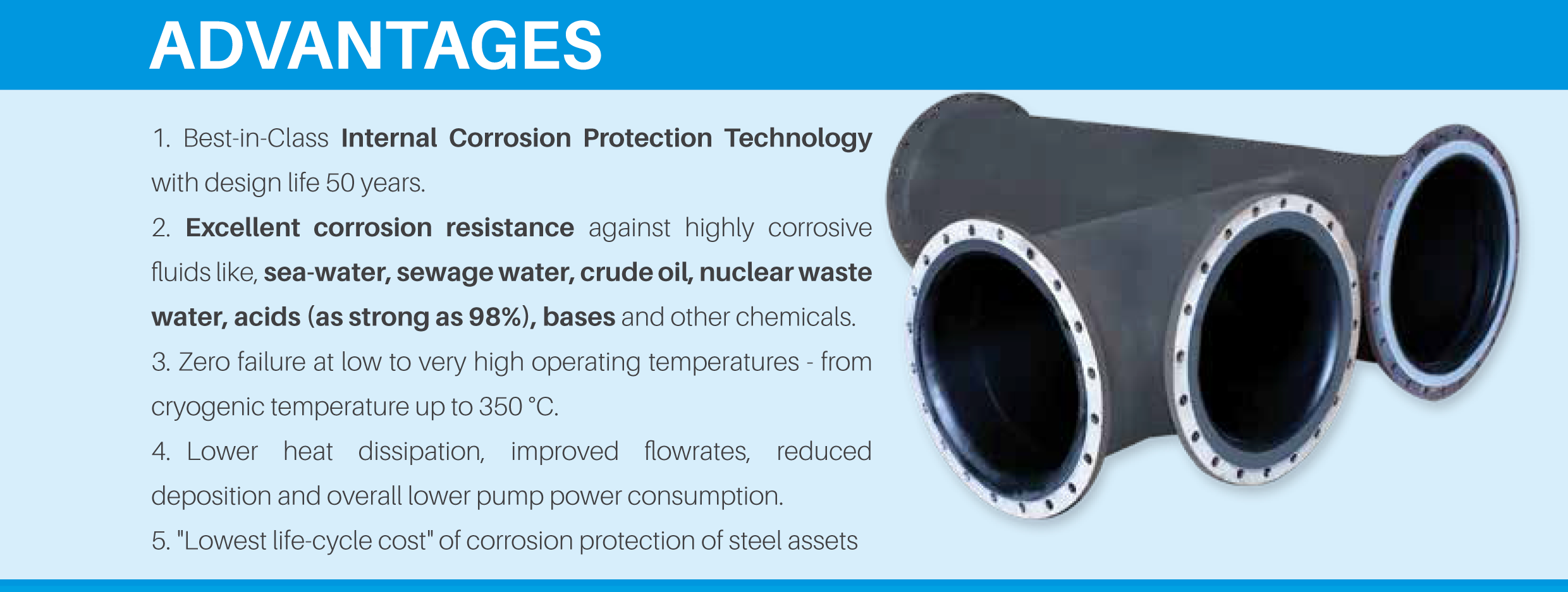

Rotolining / Polymer Lining is the Best-in-Class Corrosion Protection Technology, effective against crude oil, saline water, waste water in addition to the most corrosive chemicals like acids, alkalis, oxidizers, solvents, and salts. It can be applied on Carbon Steel pipes, spools, flowlines, fittings, vessels and process equipment etc. in form of a protective layer (internal polymer coating / lining) of 2 to 11mm thickness, enriched with corrosion resistant additives. The result is fewer breakdowns & reduced maintenance costs. It leads to significantly longer & reliable uptime when compared to other Corrosion Protection techniques. The smooth polymer surface also results in smoother flow and lesser pump power consumption. Whenever this technology is used, there is significant reduction in the life cycle costing of the assets as well. Polycon is the pioneer and the only company in the UAE to offer Rotolining / Polyethylene Lining technology to the Oil & Gas, Marine, Desalination, Chemicals and the Process industries in the region.

APPLICATIONS

-

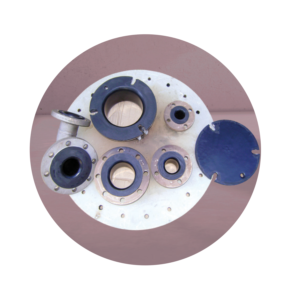

- Carbon Steel Pipes, Spools and Fittings.

- Skids, Vessels, Headers, Scrubbers, Agitators, Tankers.

- Water and Chemical Injection Systems

- Process Equipment

- Marine Piping Systems and Equipment ( BWTS and others)

INDUSTRIES

- Oil & gas

- Marine & Ship-building

- Chemicals, Petrochemicals

- Fertilizers

- Power & Desalination Plants

- Sewage Treatment Plants

- MEP & Maintenance of City Water Transmission Systems